6. Tutorial

Video Links (in Chinese): GiftBTE软件教程-4:FinFET案例及数据可视化处理

6.1 CASE 1: Temperature profiles in Fin field-effect transistors

Here is an example of predicting temperature rise of FinFET using mesh files generated from COMSOL software and phonon properties calculated from ALAMODE package. The files are listed as the following:

input

├── CONTROL

├── GEOMETRY

├── PHONON

├── FinFet_bound_1w4.mptxt

├── inputbc_Finfet.dat

├── heatfile.xt

├── materials

├── Si

├── tau300K_pure.dat

Create a CONTROL file

The CONTROL file of this example is typed as the following:

Order: //1:first order; 2:second order; 2limit: limited second order

2

IterativeScheme: // Synthetic or Sequential

Synthetic

MatrixSolver: // LU or BICGSTAB

LU

ResidualTemp:

1e-5

ResidualFlux:

1e-2

This CONTROL file tells the GiftBTE to adopt 2nd order spatial discretization and synthetic iterative scheme. The MatrixSolver is LU factorization. The convergence criteria for temperature and heat flux are also specified.

Create a GEOMETRY file

The GEOMETRY file of this example is typed as the following:

GeometryDimension://1 or 2 or 3

3

ScaleX:

1e-9

ScaleY:

1e-9

ScaleZ:

1e-9

BCFile:

input/inputbc_Finfet.dat

MeshfileType: // COMSOL or MSH

COMSOL

MeshFile=

input/FinFet_bound_1w4.mptxt

HeatfileType: //COORDINATE or REGION

REGION

HeatFile=

input/heatfile.xt

Attention: MeshType=”COMSOL” represents that the mesh file is generated from COMSOL software.

HeatType= “REGION” represents that uniform heat source needs to be added in each geometry region.

Create FinFet_bound_1w4.mptxt file in COMSOL

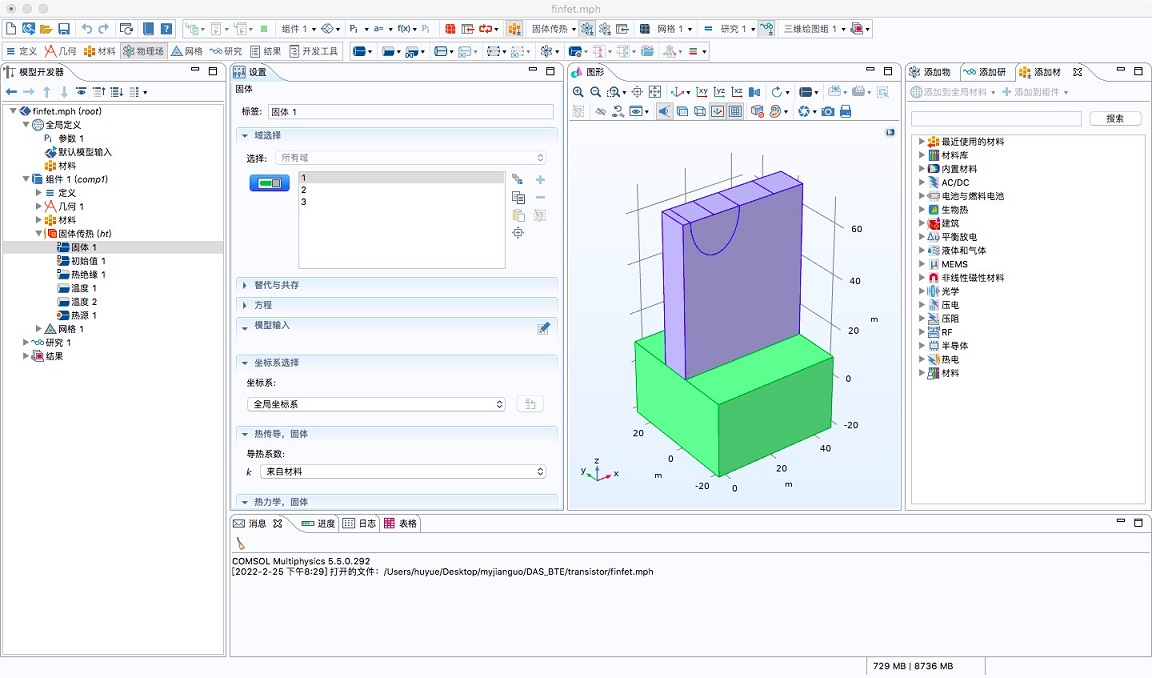

Build geometry in COMSOL

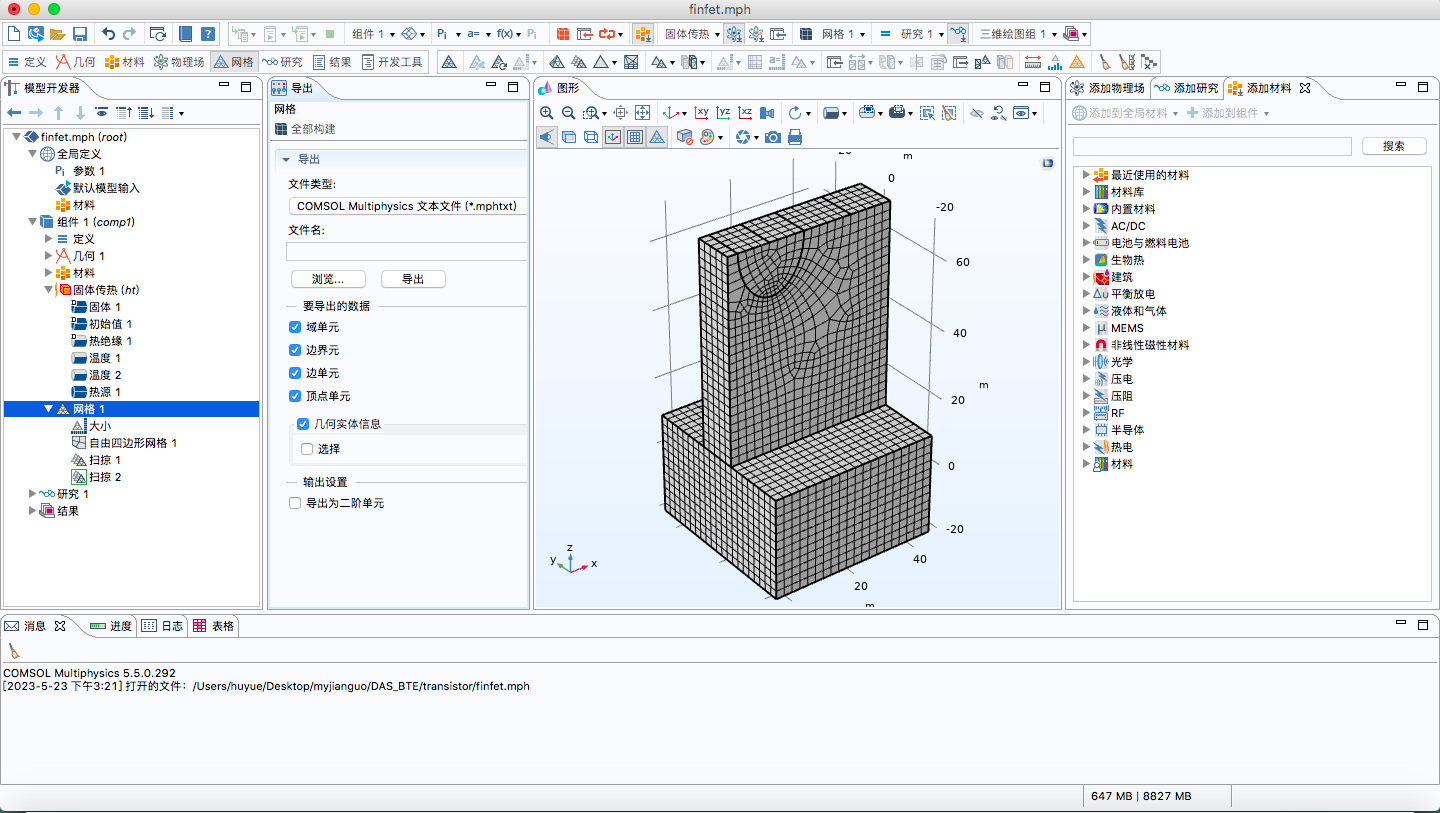

Generate mesh

Export the mesh file (.mphtxt):

Created by COMSOL Multiphysics.

Major & minor version

0 1

1 # number of tags

Tags

5 mesh1

1 # number of types

Types

3 obj

--------- Object 0 ----------

0 0 1

4 Mesh # class

4 # version

3 # sdim

16930 # number of mesh vertices

0 # lowest mesh vertex index

Mesh vertex coordinates

-5 -25 -20

-3.0000000000000004 -25.000000000000007 -20.000000000000007

-5 -23.099999999999994 -20

-5 -25.000000000000004 -18

-1 -25.000000000000007 -20.000000000000004

-2.9999999999999964 -23.100000000000005 -20

-3.0000000000000004 -25 -18

-5 -21.199999999999996 -20

-5 -23.099999999999994 -18

-5 -25.000000000000004 -15.999999999999998

...

Create inputbc_FinFET.dat file

The inputbc_FinFET.dat is typed as the following:

18 #Number of boundaries

BoundaryIndex BoundaryType BoundaryValue //BoundaryIndex starts from 1 //BoundaryType=1:thermalizing; BoundaryType=2:diffusely reflecting; BoundaryType=3:specularly reflecting; BoundaryType=5:Interfacial; BoundaryType<0:periodic

1 3 0

2 2 0

3 1 300

4 3 0

5 2 0

6 3 0

8 1 300

9 2 0

10 2 0

11 2 0

12 1 300

14 2 0

15 2 0

16 1 300

18 1 300

19 1 300

20 3 0

21 2 0

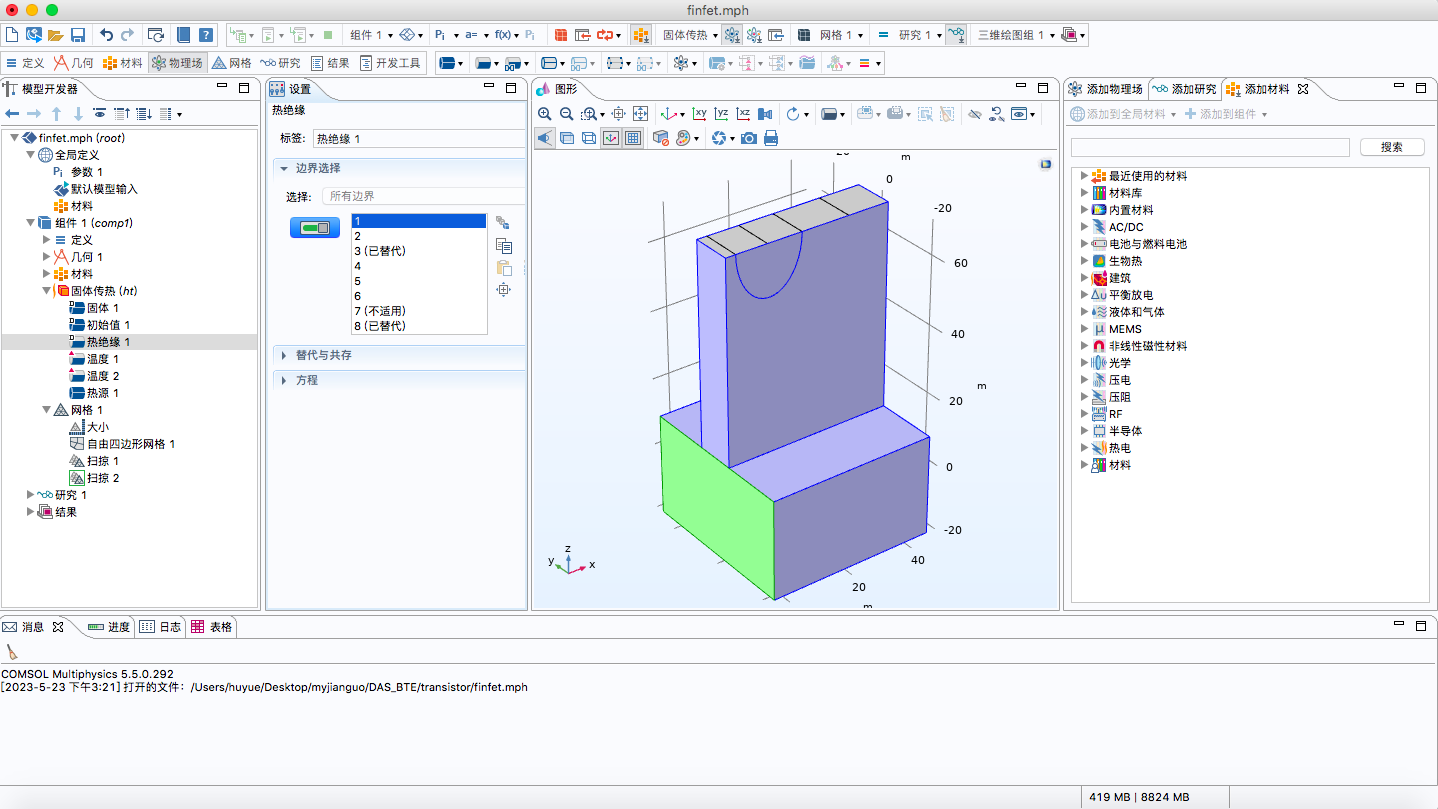

How to know the index of each boundary, see COMSOL

Attention: the boundary index of each boundary in the inputbc_FinFET.dat file is equal to the index in COMSOL software. Meanwhile, boundaries that do not need to be specified, such as some internal boundaries, should not be typed in the inputbc_FinFET.dat.

Create heat source file

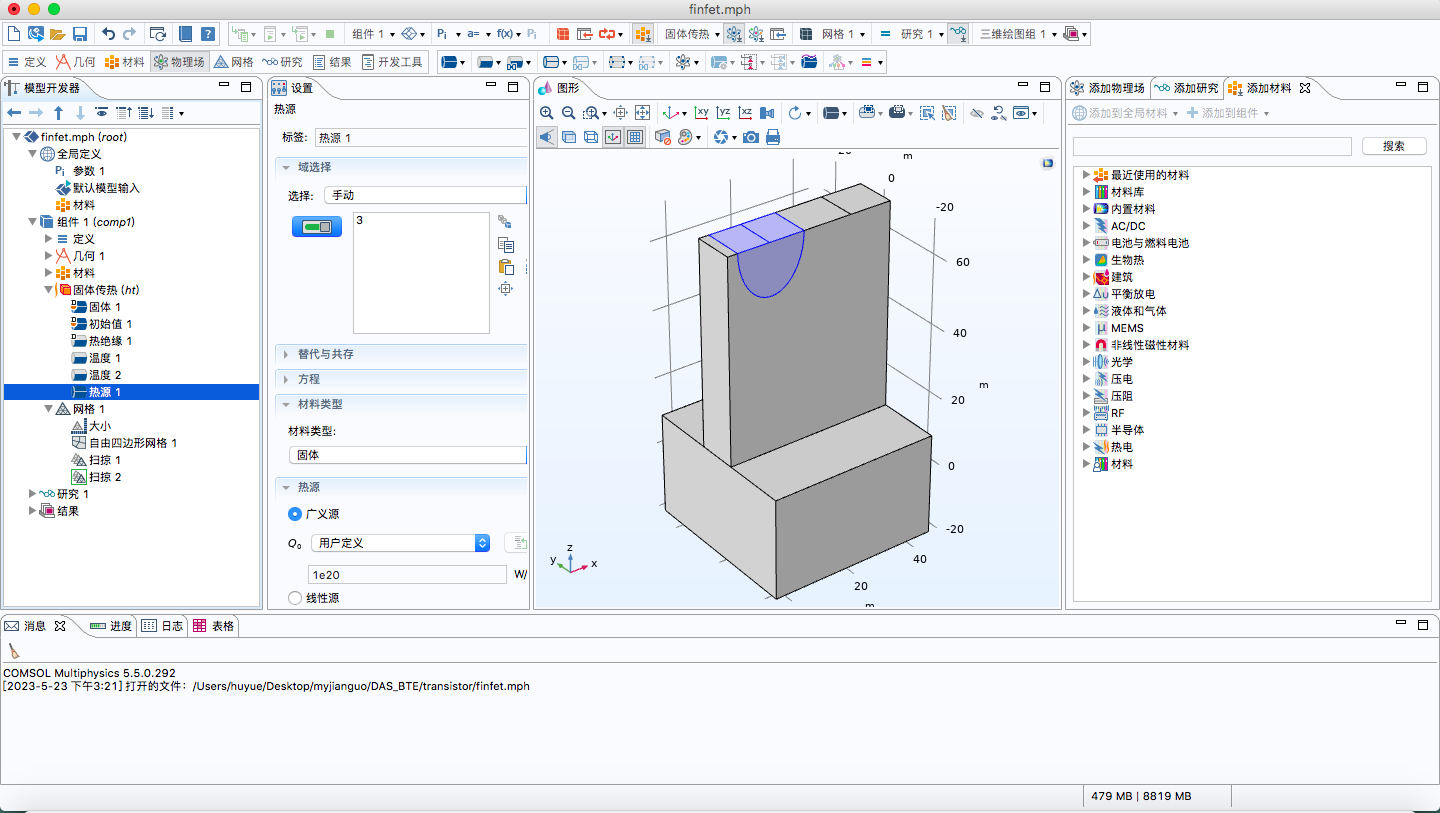

Set heat source in COMSOL. As shown below, the highlighted semi-cylinder region (i.e., the 3rd region) is where the heat source needs to be added.

The heatfile.txt is typed as the following (HeatType = “REGION”):

3 # geometry: #geo index - heat index start from 0

1 0

2 0

3 1e19

Attention: the geometry index of each geometry/region in the heatfile.txt file starts from “1”

Create a PHONON file

The PHONON file is typed as the following:

MaterialNumber=

1

BandNumber=

15

MaterialFile 1: ALAMODE

input/materials/Si/tau300K_pure.dat

GeometryMaterialType: #geometryindex and matterindex both start from 1

1 1

2 1

3 1

MaterialDimension:

3

Ntheta:

2

Nphi:

4

Attention: the geometry index of each geometry/region in the PHONON file starts from “1”. “ALAMODE” represents using phonon properties calculated from the ALAMODE package as the input

tau300K_pure.dat (created by ALAMODE Tutorial 7 phonon Lifetime)

#Result analyzer ver. 1.0.5

#Input file : si222_50_01.result

#Phonon lifetime at temperature 300 K.

#kpoint range 1 3107

#mode range 1 6

# ik, is, Frequency [cm^{-1}], Lifetime [ps], |Velocity| [m/s], MFP [nm], Multiplicity, Thermal conductivity par mode (xx, xy, ...) [W/mK]

1 1 1.09737e-10 0 0 0 1 0 0 0 0 0 0 0 0 0

1 2 1.09737e-10 0 0 0 1 0 0 0 0 0 0 0 0 0

1 3 1.09737e-10 0 0 0 1 0 0 0 0 0 0 0 0 0

1 4 509.651 1.6395 0 0 1 0 0 0 0 0 0 0 0 0

1 5 509.651 1.6395 0 0 1 0 0 0 0 0 0 0 0 0

1 6 509.651 1.6395 0 0 1 0 0 0 0 0 0 0 0 0

2 1 9.27625 5695.14 4347.12 24757.5 8 0.0988522 2.52613e-07 2.52613e-07 2.52613e-07 0.0988522 2.52613e-07 2.52613e-07 2.52613e-07 0.0988522

2 2 9.27625 5695.14 4347.12 24757.5 8 0.0990608 2.40786e-07 2.40786e-07 2.40786e-07 0.0990608 2.40786e-07 2.40786e-07 2.40786e-07 0.0990608

6.2 CASE 2: Thermal conduction in nano-porous media

Here is an example of predicting thermal conduction in nano-porous media using mesh files generated from GMSH software and phonon properties calculated from ShengBTE. The files are listed as the following:

input

├── CONTROL

├── GEOMETRY

├── PHONON

├── gms2685.msh

├── inputbc_2D_porous.dat

├── materials

├── Ge

├── ShengBTEFile

├── BTE.omega

├── BTE.qpoints_full

├── BTE.v

├── BTE.w_final

├── CONTROL

Create a CONTROL file

The CONTROL file of this example is typed as the following:

MatrixSolver: // LU or BICGSTAB

BICGSTAB

This CONTROL file tells the GiftBTE to adopt the BICGSTAB solver. Other commands retain the default settings.

Create a GEOMETRY file

The GEOMETRY file of this example is typed as the following:

GeometryDimension: //1 or 2 or 3

2

ScaleX:

5e-7

ScaleY:

5e-7

ScaleZ:

5e-7

BCFile:

input/inputbc_2D_porous.dat

MeshfileType: // COMSOL or MSH

MSH

MeshFile:

input/gms2685.msh

Attention: MeshType=”MSH” represents that the mesh file is generated from GMESH software.

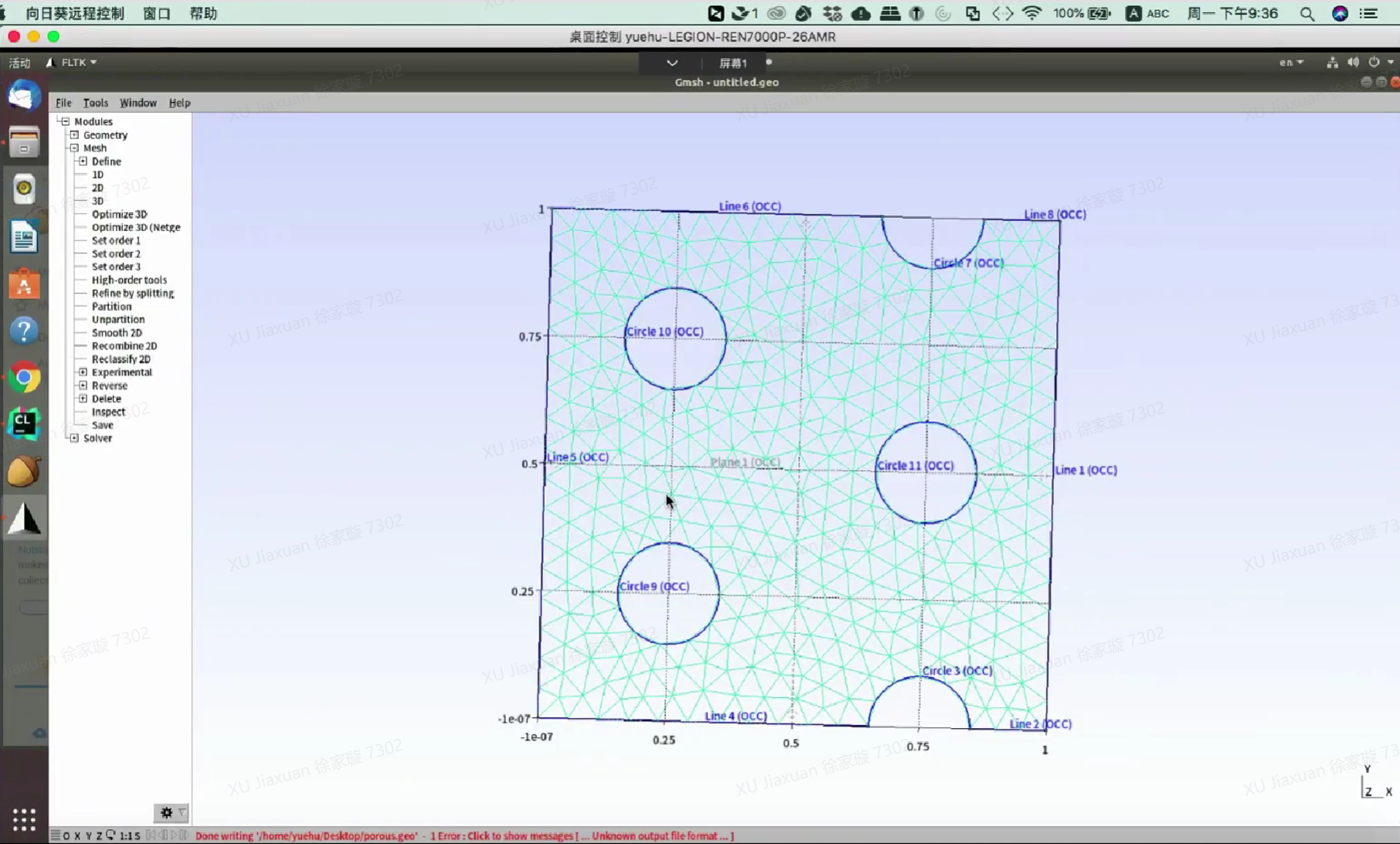

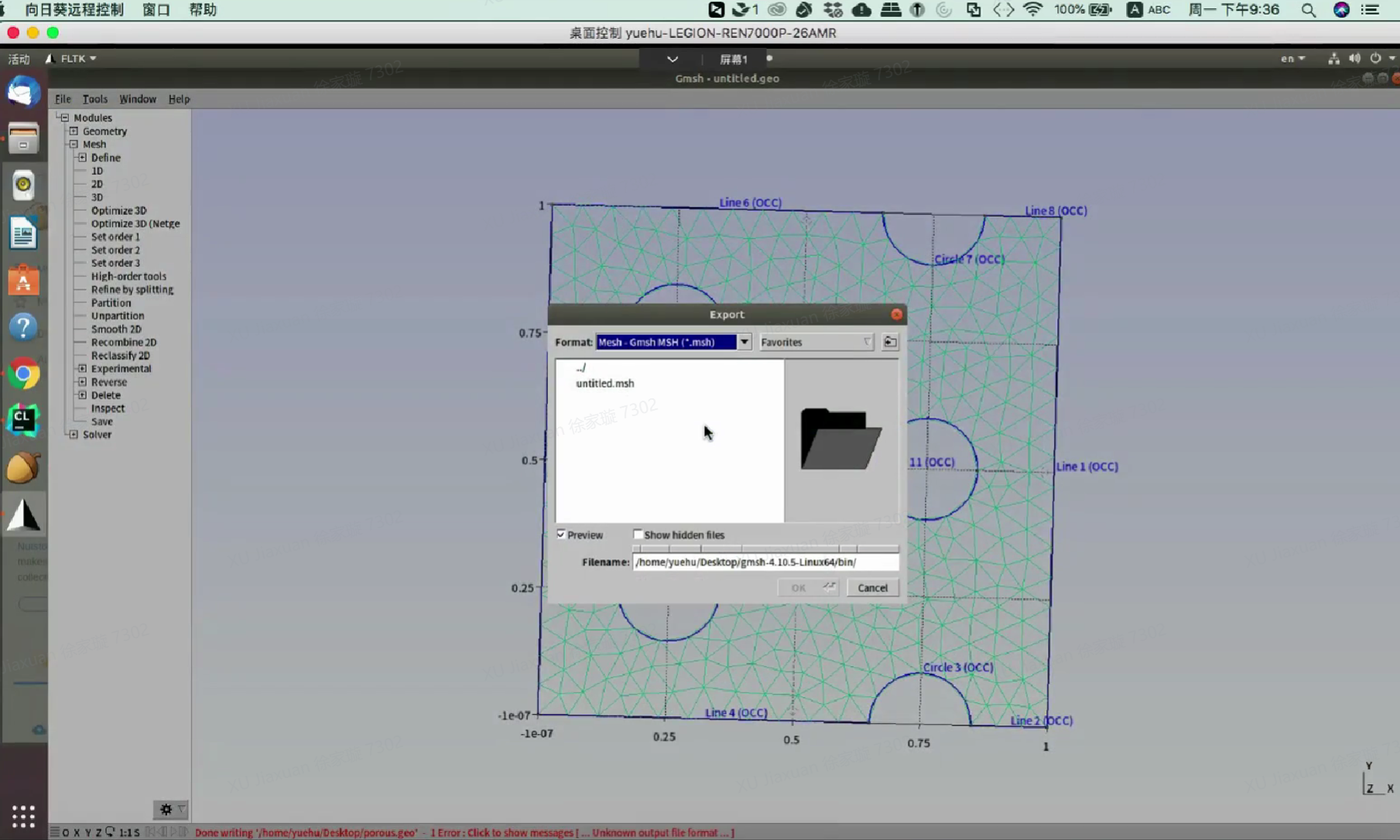

Create gms2685.msh file in Gmsh

Built geometry and mesh in GMESH

Export the mesh file (.msh):

$MeshFormat

4.1 0 8

$EndMeshFormat

$Entities

11 11 1 0

1 1 0 0 0

2 1 1 0 0

3 0.85 0 0 0

4 0.65 4.491424253481369e-15 0 0

5 0 0 0 0

6 0 1 0 0

7 0.65 1.000000000000004 0 0

8 0.85 1 0 0

9 0.35 0.25 0 0

10 0.35 0.75 0 0

11 0.85 0.5 0 0

1 0.9999999000000001 -9.999999994736442e-08 -1e-07 1.0000001 1.0000001 1e-07 0 2 1 -2

2 0.8499999 -1e-07 -1e-07 1.0000001 1e-07 1e-07 0 2 3 -1

3 0.6499999000000001 -1.000000000028756e-07 -1e-07 0.8500000999999999 0.1000001 1e-07 0 2 3 -4

4 -1.000000000028756e-07 -1e-07 -1e-07 0.6500001 1e-07 1e-07 0 2 5 -4

...

Create inputbc_2D_porous.dat file

The inputbc_2D_porous.dat is typed as the following:

11 #number of boundaries

BoundaryIndex BoundaryType BoundaryValue //BoundaryIndex starts from 1 //BoundaryType=1:thermalizing; BoundaryType=2:diffusely reflecting; BoundaryType=3:specularly reflecting; BoundaryType=5:Interfacial; BoundaryType<0:periodic

1 -5 0

2 3 0

3 2 0

4 3 0

5 -1 1

6 3 0

7 2 0

8 3 0

9 2 0

10 2 0

11 2 0

Attention: boundary 1 and boundary 5 are a pair of periodic boundaries where a temperature difference of 1K is applied.

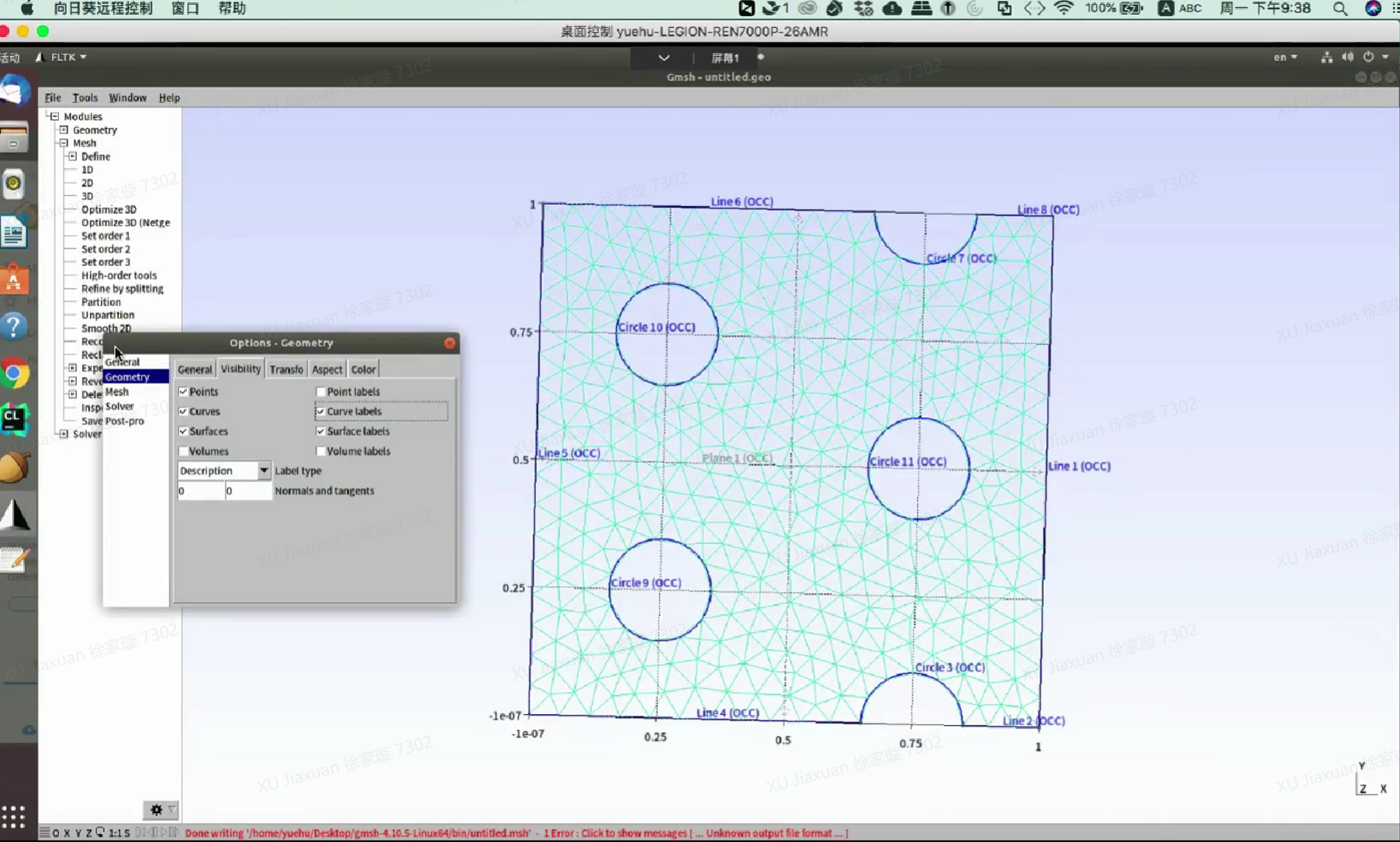

How to know the index of each boundary, see GMESH

Attention: the boundary index of each boundary in the inputbc_2D_porous.dat file is equal to the index in GMESH software.

Create a PHONON file

The PHONON file is typed as the following:

MaterialNumber=

1

BandNumber=

12

MaterialFile 1: ShengBTE

input/materials/Ge/ShengBTEFile

GeometryMaterialType: //geometryindex and matterindex both start from 1

1 1

MaterialDimension:

3

Ntheta:

8

Nphi:

8

Attention: the geometry index of each geometry/region in the PHONON file starts from “1”. “ShengBTE” represents using phonon properties calculated from the ShengBTE (version >= 1.1.1) as the input. Five files from the ShengBTE are needed, i.e., BTE.omega, BTE.qpoints_full, BTE.v, BTE.w_final, CONTROL (CONTROL file in ShengBTE).